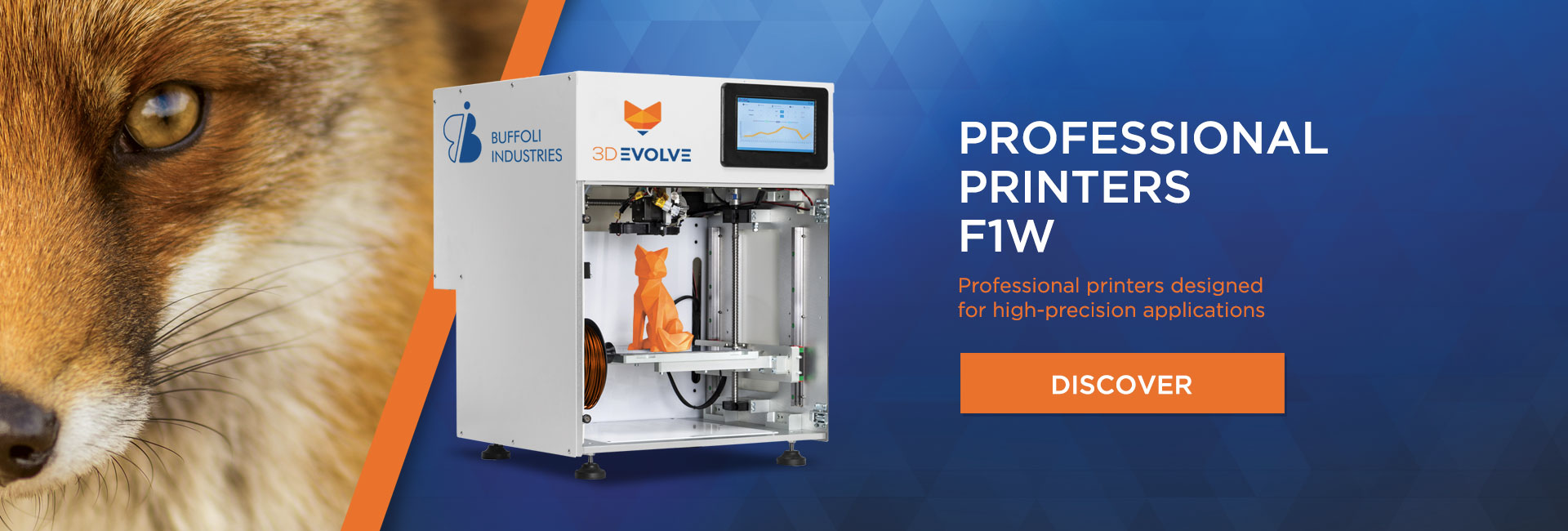

3D Evolve high precision 3D printer distribution

3D ETPLUS, as part of Buffoli Industries is a preferred partner for 3D Evolve, another Buffoli Industries company focused on creating a high precision, high temperature 3D printer. 3D ETPLUS is the licensed distributor of their high precision high temperature F1W printer for Switzerland. Why the F1W? Read on to better understand this fabulous machine!

High precision FDM 3d printer

So what makes the F1W a high precision FDM 3D printer? How does it achieve 5µm (0.005mm) repeatable tolerance on printed parts?

Precision motion system

As you may have noticed in the video below, the printer uses preloaded ball screws for motion on all 3 axes (X, Y and Z). The individual axis position’s precision is 0.001mm, or a different way to write that is: 1µm! This means that the toolhead is always exactly where it needs to be!

Precise extrusion system

The F1W uses the excellent E3D Online Hemera extruder in a single or dual configuration. In the single extruder version, you can only print a single type of material per print. In dual configuration, you can print either two different materials, or two different colors.

The Hemera uses dual-drive gears for controlling the filament flow, with a 1:3 reduction on a high precision stepper motor. Controlled by a Trinamic stepper driver, the motor motion control is further refined with 256 microsteps.

In practice, this means that the motion is incredibly precise and very smooth, giving the best possible printing results.

Precise temperature management

Not only is the Hemera used, it is additionally fitted with high precision temperature sensors using the plated-copper heatblock, titanium heatbreak and hardened steel nozzles from E3D Online.

These components are part of the E3D V6 ecosystem, which encompasses a wide range of high performance component combinations. The various options allow optimization for different requirements, all while remove compatibility questions.

The components selected by 3D Evolve offer a wide range of temperatures (maximum operating temperature of 550°C) and nozzle diameters from 0.15mm to 0.8mm. With the high quality materials and parts used, the enclosed print area, and a well-calibrated thermal management, temperatures are consistent throughout your printing process.

High temperature FDM 3D printer

The F1W is not only good for high precision parts. It also prints high temperature materials! Do you need parts out of PEEK? You’ll be hard pressed to find a better desktop machine to print your functional prototypes with.

Whether PMMA, POM, PolyCarbonate, PC-ABS, Nylon… All these materials are considered “difficult to print” on regular 3D printers.

Not so on the F1W. The main difficulty to achieve successful prints with these advanced materials is a high and precise temperature management during the printing and cooling process. This is one of the areas where the F1W excels.

Enclosed, passively heated build volume

The F1W fully encloses the print volume. No air drafts getting in or out of the printer unless you leave the door open. The custom-designed print bed allows a high temperature of nearly 200°C! In such a small volume, it acts as a very good heater. With some careful programming, the print volume can be preheated to a desired temperature before the printing begins. This means you get perfect printing conditions for your parts!

High temperature sensor, high temperature materials

The F1W, as mentioned before, uses a plated copper heatblock. This is significant because aluminum heatblocks start to lose rigidity and shape around 400°C.

The copper heatblock retains perfect printing characteristics all the way up to 550°C.

Similarly the titanium heatbreak is better suited for high temperature printing, as it more effectively prevents transmission of heat upwards into the extruder body.

This means a very short filament temperature transition, yielding the best possible print results!

If you have any questions about the F1W, you can read up more on the 3D Evolve website, or reach out with your questions!

Pingback:Desktop CNC? Happy encounters at IMTS 2022 - 3D ETPLUS

Pingback:CNC im Büro? Sympathisches Treffen auf der IMTS 2022 - 3D ETPLUS

Pingback:CNC da tavolo? Un incontro piacevole all'IMTS 2022 - 3D ETPLUS